Carbon Fiber Rim Mold Optimization

Engineering Internship at Boyd Cycling & Time Bicycles

Optimized RTM carbon-rim fabrication processes, analyzed mold geometry, and resolved resin distribution issues to ensure consistent structural integrity and performance.

Project Overview

A detailed engineering analysis and optimization of the Resin Transfer Molding (RTM) process for high-performance carbon fiber bicycle rims.

The Challenge

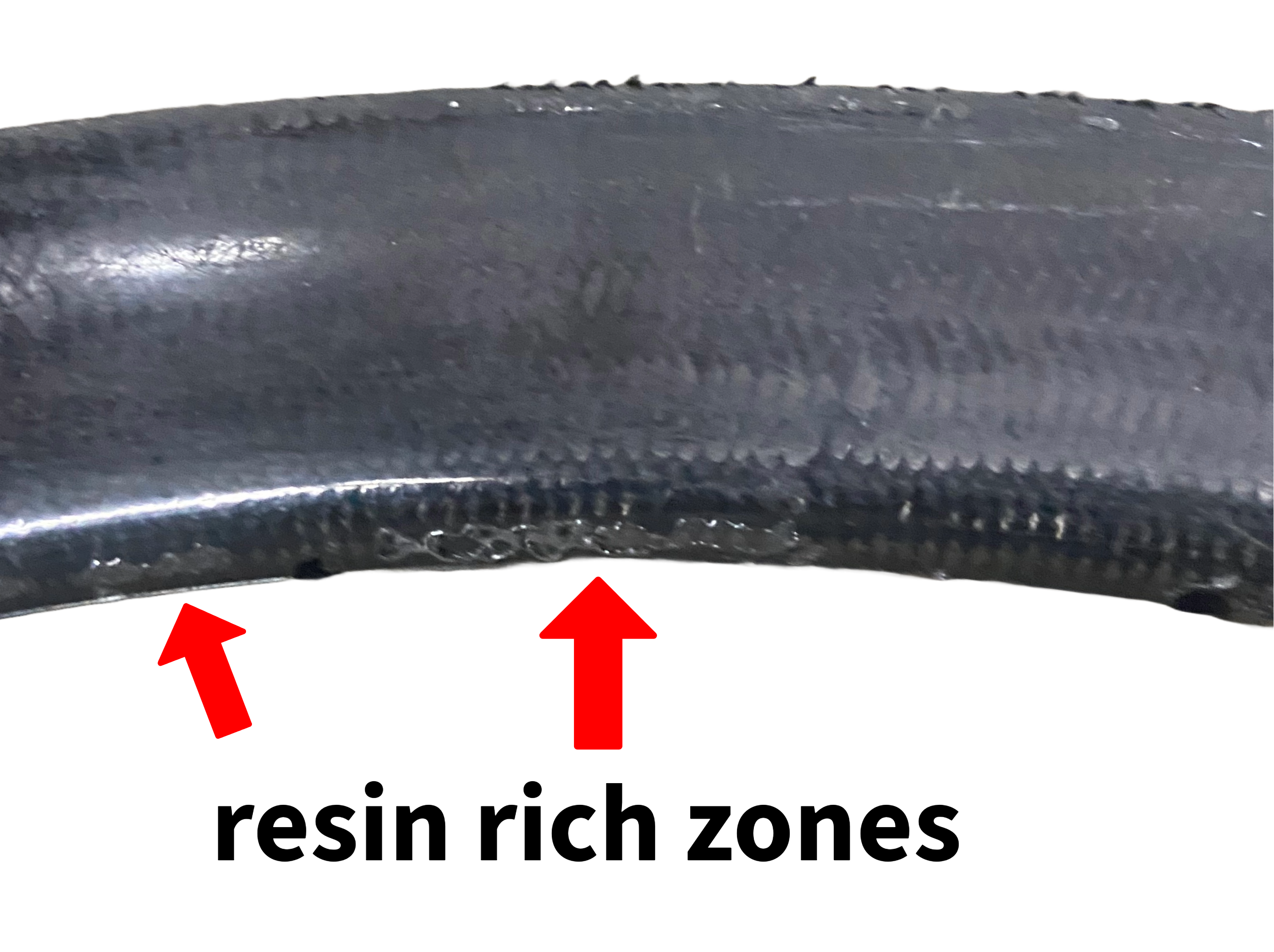

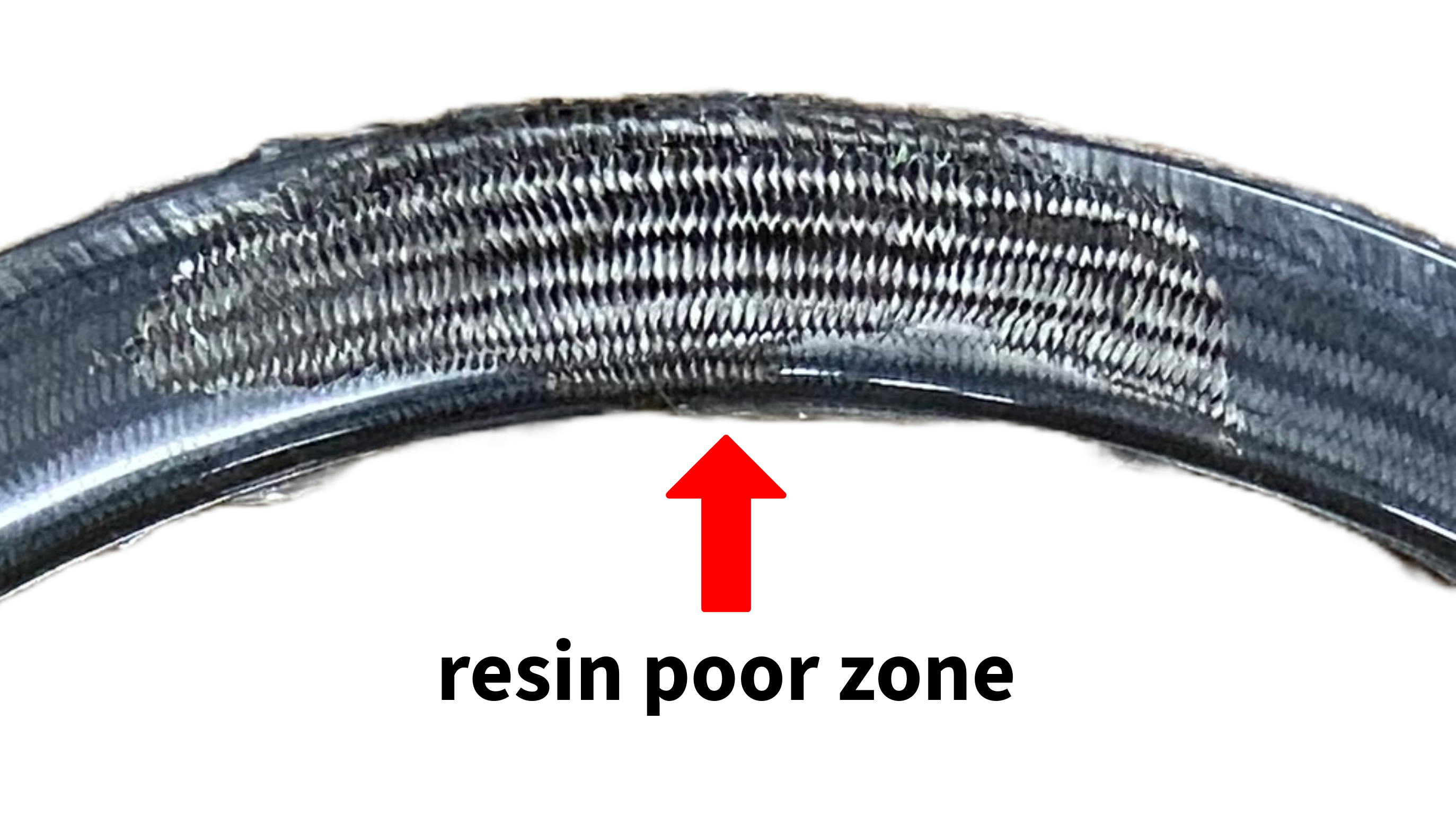

Boyd Cycling faced challenges with inconsistent resin distribution in their carbon rim production, leading to potential structural weaknesses and cosmetic defects. The goal was to optimize the mold geometry and injection process to ensure uniform resin flow and cure.

Engineering Solution

I conducted a comprehensive analysis of the RTM process, tracking resin flow patterns and identifying critical variables. By adjusting mold temperatures, injection pressures, and layup schedules, I was able to eliminate resin-rich and resin-poor zones, resulting in a higher quality product.

Key Technologies

Manufacturing Optimization

Refining the Resin Transfer Molding (RTM) process

Carbon fiber preform positioned in the mold prior to resin injection.

Automated winding of carbon fiber filaments.

Process Analysis

I conducted a detailed analysis of the RTM process, tracking resin flow and cure cycles. By identifying variables that led to inconsistencies, we were able to optimize the injection parameters and mold temperatures.

Defect Resolution

A key focus was eliminating resin-rich and resin-poor zones. Through careful adjustment of the process, we achieved a more uniform resin distribution, resulting in stronger, lighter, and more reliable rims.

Identifying areas of excess resin accumulation.

Identifying areas of insufficient resin penetration.

Hand-Wrapped Carbon Prototyping

In addition to automated processes, I worked on a specialized project involving the hand-wrapping of bike frame wax molds using Non-Crimp Fabric (NCF). This hands-on approach allowed us to test complex geometries and layup schedules that were difficult to achieve with automated machinery initially.

By manually applying the NCF, we could precisely control fiber orientation in critical stress zones, providing valuable data on how manual intervention could enhance the structural integrity of specific frame sections before scaling to full production.

Application of Non-Crimp Fabric (NCF) to a wax mold for prototype testing.