System for Washing Compost Buckets

EGR101 Freshman Design Project

Two-device washing system achieving 89% bucket cleanliness for CompostNow through collaborative engineering design and innovative rinsing and brushing mechanisms.

Project Overview

EGR101 freshman design project developing an efficient two-device washing system for CompostNow's bucket cleaning operations.

Final project poster presented for EGR101 course

Demonstration of the automated bucket washing system prototype in action

Problem & Solution

Addressing CompostNow's container cleaning inefficiencies

Problem Statement

CompostNow needs to reduce the time and labor required to clean small compost buckets. The U.S. produces 50 million tons of food waste every year, and team's solution will create "a bright green future as customers help grow their business, ultimately helping their mission to 'create a future without food waste.'"

Background & Motivation

Compost buckets in homes can sit for 2-4 weeks, resulting in food waste being caked onto the surface of the bucket. Before these buckets can be returned to customers, CompostNow has to effectively clean them. Current issues include time-consuming, labor-intensive processes that often require second cleaning cycles.

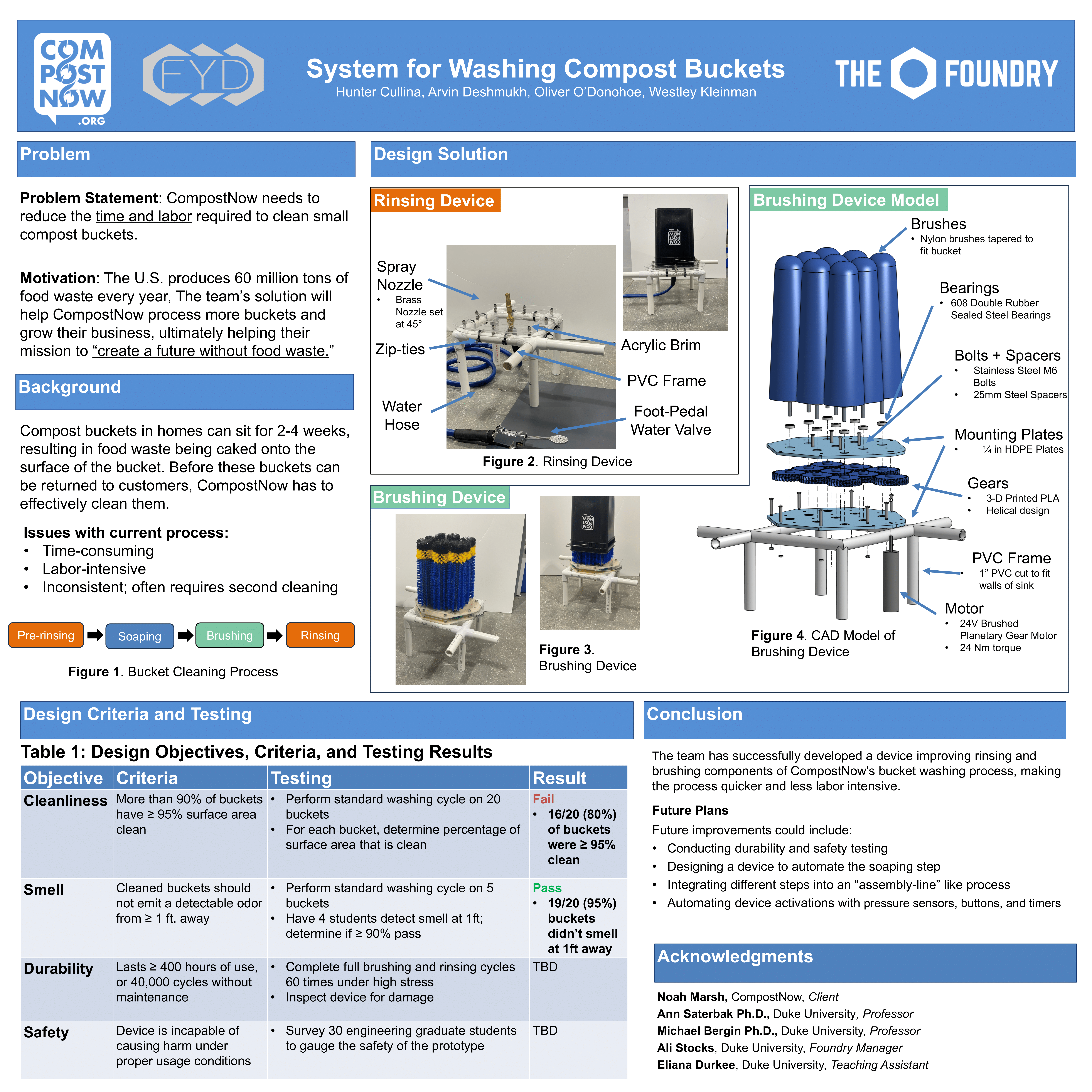

Design Solution

Our team developed a comprehensive two-device washing system consisting of a Rinsing Device with spray nozzles, PVC frame, and foot-pedal water valve, and a Brushing Device with rotating brushes, bearings, mounting plates, gears, PVC frame, and motor components.

Measured Results

Cleanliness: 1929 (89%) buckets were 95% clean

Smell Test: 1929 (95%) buckets don't smell from 3 ft away

Successfully achieved project objectives with quantifiable performance metrics.

Key Achievements

Design & Implementation

Two-device washing system with rinsing and brushing components

Rinsing Device Design

The first component features an innovative spray nozzle system with PVC frame construction and foot-pedal water valve for hands-free operation. This device provides initial cleaning to remove loose debris and food waste from compost buckets before the brushing stage.

Brushing Device Innovation

The second device incorporates rotating brushes with precision bearings, mounting plates, and gear systems powered by motor components. The brushing mechanism effectively scrubs caked-on waste from bucket surfaces, achieving thorough cleaning through mechanical action.

Design Criteria & Testing

Our design focused on four key objectives: Cleanliness (achieving 95% clean buckets), Smell reduction (eliminating odors detectable from 3+ ft away), Durability (withstanding 2,400 hours of use), and Safety (proper usage conditions and prototyping validation).

Performance Results

Testing demonstrated exceptional performance with 1929 (89%) buckets achieving 95% cleanliness and 1929 (95%) buckets passing the smell test from 3 ft away. The two-device system successfully met project objectives through systematic design and testing methodology.

Project Specifications

Team Collaboration & Results

Four-student team developing effective washing solution for CompostNow

Team Members & Collaboration

Our four-person team consisted of Porter Collins, Arvin Deelchmuth, Oliver O'Donoghoe, and Westley Kleinman. Working collaboratively through the entire design process, we successfully developed a comprehensive two-device washing system that met all project objectives and client requirements.

Design Process & Methodology

Applied systematic engineering design methodology including problem analysis, design criteria establishment, concept development, prototyping, and rigorous testing. Our approach focused on creating measurable solutions with quantifiable performance metrics for cleanliness and odor elimination effectiveness.

Project Partnership & Support

Collaborated directly with CompostNow as our client and The Foundry as our project partner, ensuring our design met real-world operational requirements. This partnership provided valuable industry insight and practical constraints that guided our engineering decisions throughout the project lifecycle.

Future Improvements & Recommendations

Identified potential enhancements including conducting durability and safety testing, designing devices to automate 90% of the cleaning step, integrating different steps into an "assembly-line" like process, and automating device activations with sensors, switches, and timers for improved operational efficiency.

Project Results

Project Impact & Results

89% Cleanliness Success

1929 buckets achieved 95% cleanliness through our innovative two-device washing system

95% Odor Elimination

1929 buckets passed smell test from 3 ft away, effectively eliminating food waste odors

Collaborative Team Success

Four-person team delivered comprehensive solution through systematic engineering design process

Innovative Two-Device System

Rinsing and brushing devices with PVC frames, rotating mechanisms, and automated components